Do you have a technical challenge? Get in touch with us

-

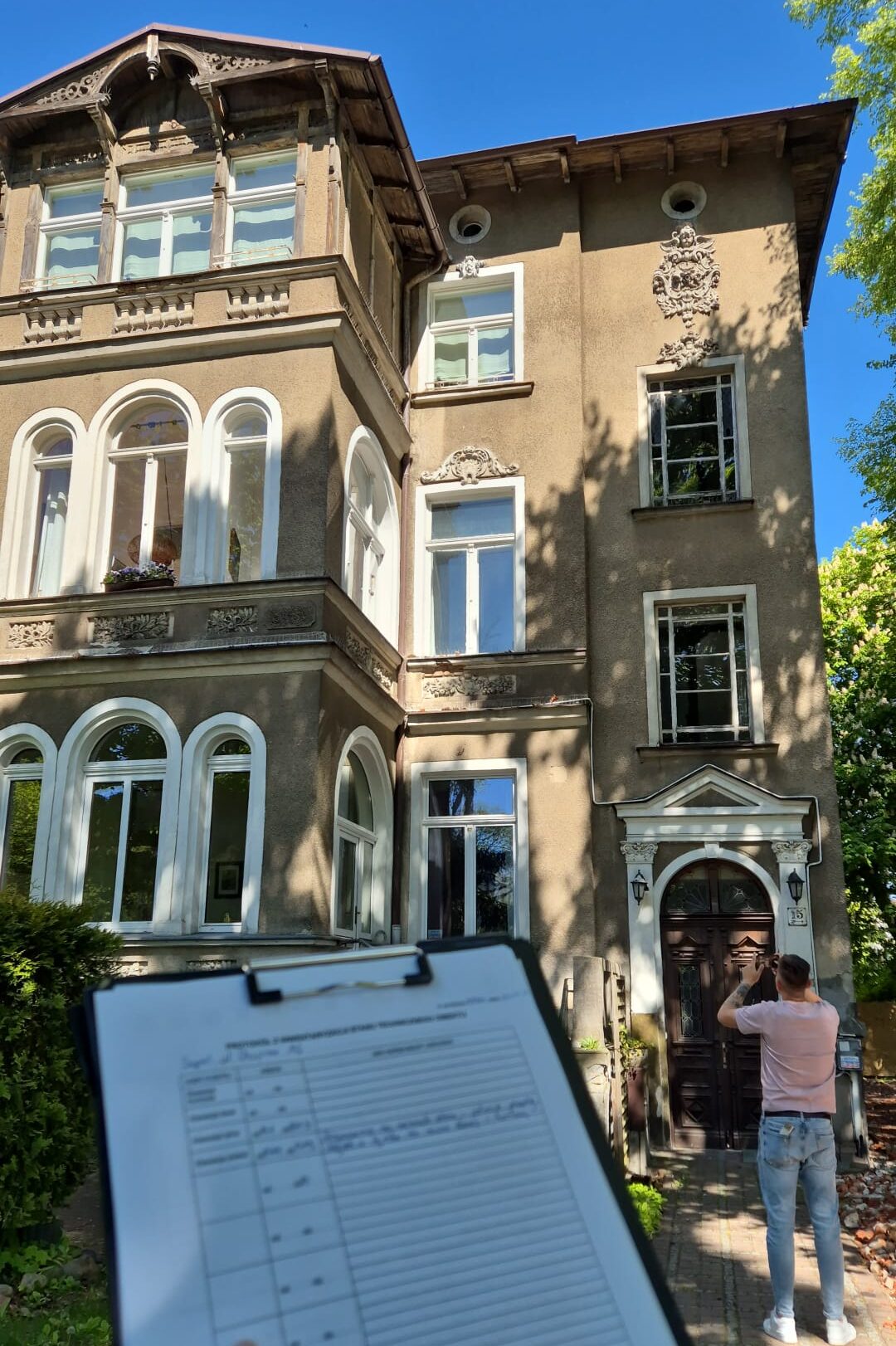

Geotechnical investigation

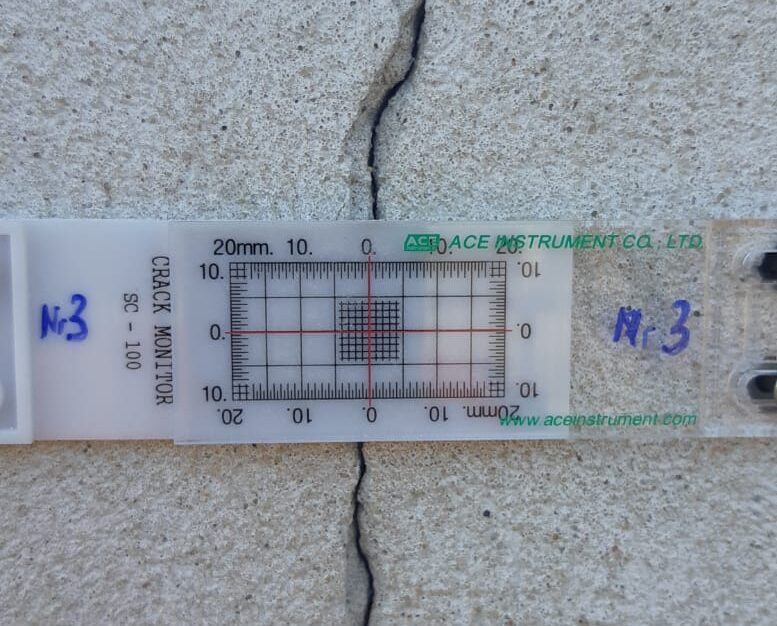

Structural monitoring

-

All industries

Geotechnical testing and structural monitoring ensure building safety and minimize the risk of settlement or damage. Forecasting and precise measurements allow for project optimization and cost reduction in future maintenance.

Computational forecasts, pile load tests, and settlement analysis enable better adaptation of foundations to soil conditions. Our solutions support risk management and enhance the durability of building structures.

Structural monitoring and foundation testing are crucial for energy facilities such as power plants and wind farms. Our technologies help control the impact of vibrations on critical infrastructure and verify the quality of geotechnical work.

Pile load testing is carried out at an early stage of bridge construction. Continuous monitoring and structural analysis help detect damages in bridges, viaducts, and roads early, increasing user safety and optimizing maintenance costs.

Vibration measurements and track monitoring assess the impact of loads on the stability of embankments and railway bridges. Our studies help minimize failure risks and enhance the durability and safety of railway infrastructure.

Deformation and displacement monitoring provide real-time safety assessments of tunnels during construction and operation. Our research helps mitigate risks related to settlement, leakage, and other structural damages.

-

R!SKmap